Fiber optic internet has emerged as a reliable and scalable alternative to traditional internet connectivity options. It’s particularly suitable for businesses that are struggling with poor internet speed and low bandwidth. As is the case with any new internet technology, fiber optic networks require a specific type of infrastructure.

For the end user, switching to fiber optic internet could be as simple as getting a compatible modem and router. However, service providers and business owners must have a firm understanding of different fiber network components. From transmitters, receivers, isolators, and amplifiers to optical fiber cables, there’s a lot of equipment needed to deploy fiber optic internet.

Transmitters and Receivers

A fiber-optic network transmits internet signals in the form of light. That makes both transmitters and receivers integral to the network.

A transmitter is a semiconductor device that converts electrical signals into optic signals. These optic signals are encoded into LEDs and laser diodes. Thereafter, the data is transmitted via fiber optic cables.

Likewise, a receiver is located at the other end of the fiber-optic network. It comprises a photodetector that encodes data (in the form of optic signals) and converts it into electrical signals. These electrical signals can be further relayed to the end user’s premises to provide internet connectivity.

Modern fiber-optic networks use transceivers that can both send and receive internet signals.

Fiber Optic Cables

Optical fiber cables are the driving force behind fiber optic internet. They’re the network component that facilitates the transmission of data over long distances.

Fiber optic cables are made using thin, flexible strands of glass that transmit light using total internet reflection. Each cable is made of three layers:

- Core: the innermost layer

- Cladding: the middle layer

- Coating: the protective outer covering

Both the core and cladding are made using pure silicon dioxide. Varying quantities of dopants are introduced to each layer during the manufacturing process. It’s done to ensure that the refractive index of the core is higher than that of the cladding.

The coating can be made with different materials, such as acrylate, silicone, or carbon. Its purpose is to protect the core and cladding from moisture, shocks, scrapes, etc.

The Last Mile

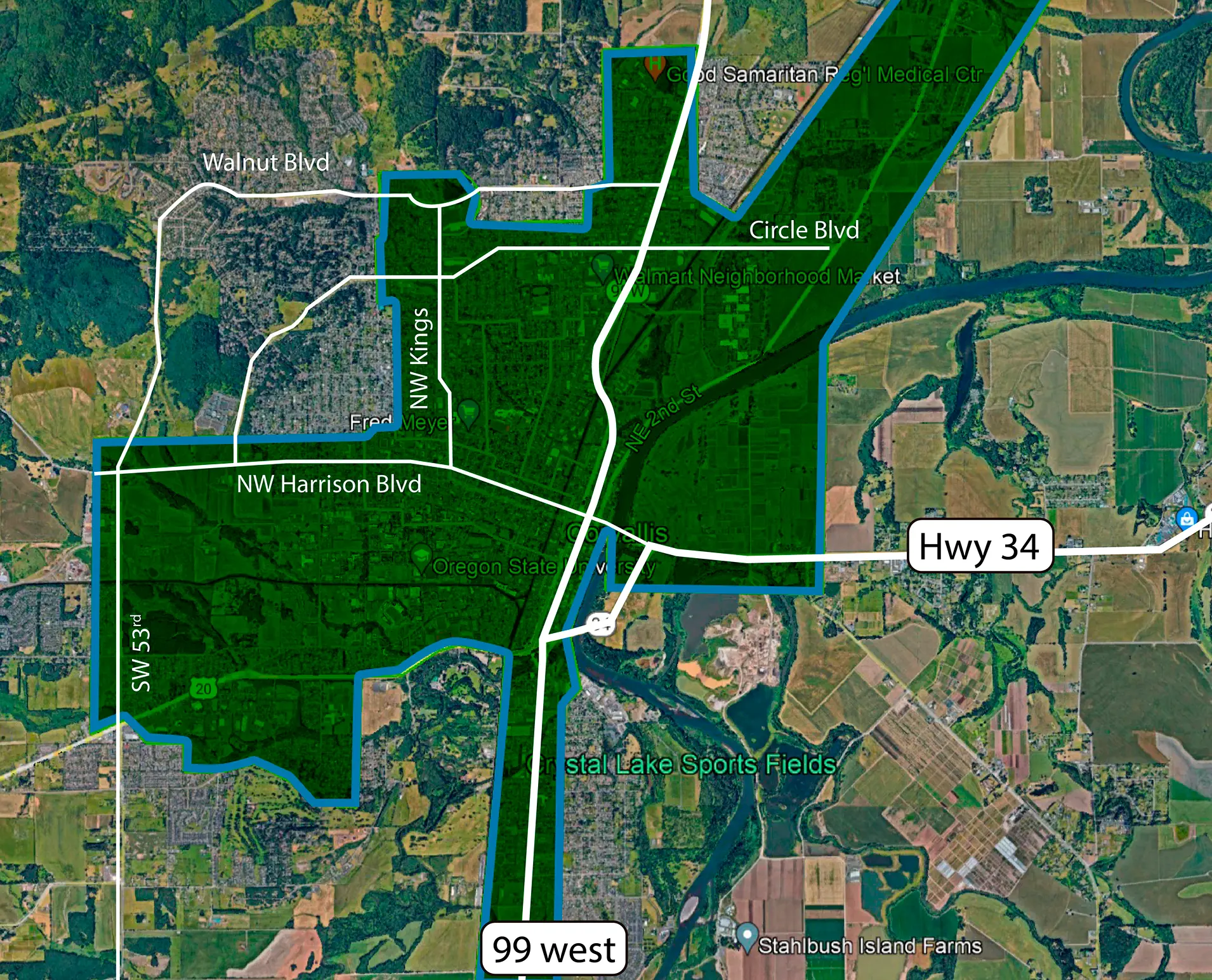

The list of fiber network components doesn’t end with transceivers and cables. Most fiber optic networks fail to provide connectivity up to the end users’ premises.

Instead, they rely on traditional network equipment, such as coaxial cables and copper phone lines. These, in turn, could cause problems with network latency, bandwidth, and speed. It’s thus important to check with your internet service provider (ISP) about the kind of last-mile infrastructure they’ve deployed.

Fulfill Your Business Internet Connectivity Needs With LS Networks

A stable, high-speed, and low latency business internet connection is crucial for modern companies. Fiber optic internet helps you overcome the limitations of traditional technologies, such as cable and DSL broadband.

At LS Networks, we specialize in powering enterprises with internet connectivity using fiber-optic networks. Reach out to us for a better understanding of fiber network components. We’ll help you determine whether business fiber internet is the right choice for your organization.